Column Dismantling Machine Price

1.Efficient disassembly capacity

2.Modularization and multifunction

3.Humanization and safety design

4.Suitability and durability

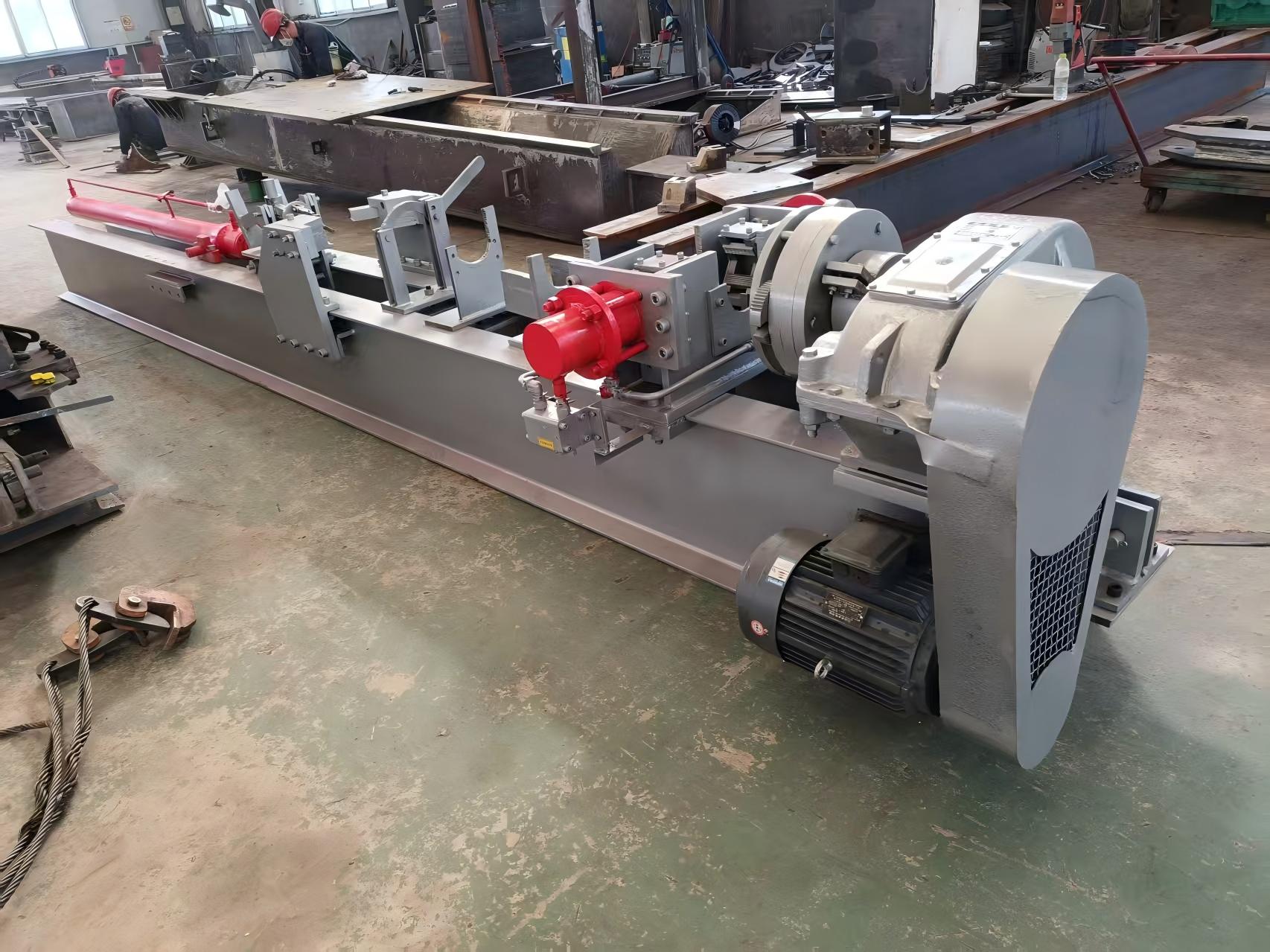

Column Dismantling Machine is a one-of-a-kind equipment in unique used for the disassembly of single hydraulic strut, in unique for the strut with serious corrosion and challenging to be dealt with by means of the usage of ordinary gear to understand mechanized disassembly. Its core characteristic is to whole the disassembly of key elements such as the strut triple valve, base, cope with body, pinnacle cowl and continue to be cylinder by means of the linkage of mechanical and hydraulic systems. The equipment adopts modular design, integrating clamping, rotating, ejection and unique multi-function units, which can adapt to the safety requirements of pillars of one-of-a-kind specifications.

Core features:

1.Humanization and protection design

Noise discount structure: the belt pressure replaces the direct connection of gear, the running noise is decrease than 75dB, and the working surroundings is improved.

Overload protection: the hydraulic gadget is outfitted with a protection valve to routinely launch the strain when the stress exceeds 14.7MPa to keep away from gear injury or personnel injury.

Labor saving operation: clamping and loosening are managed by way of the hydraulic valve group, barring guide knock, and one character can whole the complete technique operation.

2.Suitability and durability

Emulsion medium: the working medium is the water-based answer containing 5% emulsion, which has low corrosivity to tools and prolongs the carrier existence of seals.

High-strength structure: the principal shaft is hardened and tempered with 40Cr alloy steel, with hardness up to HRC28-32, sturdy bending deformation resistance and adaptability to underground extreme working conditions.

| Name | Item | Specification | Unit |

|---|---|---|---|

| Overall Dimensions (Length × Width × Height) | 6500 × 1000 × 900 | mm | |

| Machine Weight | 2500 | kg | |

| Prop Cylinder Bore(Inner Diameter) | 100-125 | mm | |

| rop Height ( Disassembly Height) | ≤4500 | mm | |

| Pump Station Pressure | 20 | MPa | |

| Flow Rate | ≤30 | L/min | |

| Working Medium | No. 46 Hydraulic Oil | ||

| Main Motor | Power | 5.5 | kW |

| Voltage | 380 | V | |

| Speed | 960 | rpm | |

| Main Reducer | High-Speed Shaft Allowable Power | 5.5 | kW |

| Low-Speed Shaft Max. Torque | Tmax= 7.4 | mm | |

| Total Reduction Ratio | I = 2.25 × 31.5 = 71.19 | ||

| Clamping Frame Hydraulic Cylinder | Working Force | 50 | kN |

| Pulling Stroke | 25 | mm | |

| Disassembly Jack | Working Force (Push/Pull) | 115 / 59 | kN |

| Working Stroke | 2100 | mm |

Safety operation specification:

1.Personal protective equipment (PPE)

Operators must wear safety helmets, anti-smash shoes, protective gloves and goggles to prevent splashed metal chips or hydraulic oil from hurting people.

Do not wear loose clothing or jewelry to avoid getting caught in rotating parts.

2.Check before starting the equipment

Hydraulic system: check whether the oil pipe connection is firm without leakage; The oil level of the oil tank shall be within the calibrated range to avoid damage to the pump station due to suction.

Electrical system: confirm that the motor is well grounded and the cable is not damaged; Emergency stop button functions properly.

Mechanical structure: check chuck, fixture, guide rail and other parts for looseness or deformation to ensure stable clamping force.

3.Operating environment requirements

The equipment shall be placed on a flat and solid ground to avoid the deviation of center of gravity due to inclination.

Sundries are forbidden to be stacked within 5m around to ensure smooth escape passage.

When used underground, ensure good ventilation to prevent explosion risk caused by gas accumulation.