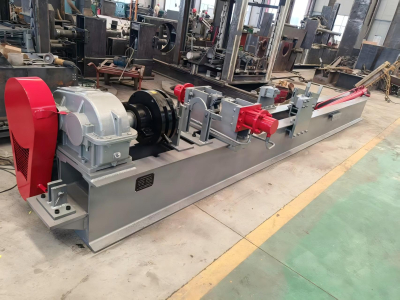

Hydraulic Cylinder Disassembly Workstation

Solve key pain points: Specially designed for pillars with severe rust and difficult manual disassembly (such as hydraulic bracket guide sleeve thread rust), replace traditional hammering violent disassembly, and improve maintenance efficiency by more than 50%46.

Reduce costs and increase efficiency: reduce the overload damage rate of equipment and extend the service life of pillars; No-load start specification (downtime> 4 hours and idling for 3-5 minutes) further ensures system safety

Hydraulic Cylinder Disassembly Workstation Operation and maintenance procedures:

1. The operator must be familiar with the working principle of the hydraulic system in the equipment, the role of hydraulic components, and the action procedures of the system.

2. The operator should frequently monitor the working conditions of the hydraulic system, especially the working pressure and the movement speed of the actuator, to ensure that the hydraulic system works stably and reliably.

3. Before starting the hydraulic system, check whether the multi-way reversing valve and all moving mechanisms are in their original state, and whether the oil level in the oil tank is normal. If the oil is abnormal, it is not allowed to start, and maintenance should be carried out.

4. With the different seasonal temperatures, the oil tank temperature has a greater impact on the operation of the system. When the temperature in the oil tank does not reach 15°C, the actuators are not allowed to start working in sequence, and the temperature must be adjusted to the allowable operating conditions before normal operation. When the oil temperature is higher than 50°C, the temperature control condition should be checked, and the temperature must also be reduced to the allowable range.

5. If the hydraulic equipment is shut down for more than 4 hours, the hydraulic pump motor should be started for 3 to 5 minutes before starting work to allow the hydraulic pump to run idly, and then it can work normally with pressure.

6. Operators are not allowed to damage the interlocking device of the electrical system; they are not allowed to damage or move the position of the operating blocks at will.

7. Without the permission of the competent department, operators are not allowed to replace the hydraulic components after self-adjustment.

8. When the hydraulic system fails, the operator shall not tamper with it privately, but shall immediately report to the maintenance department, analyze the fault and eliminate it as soon as possible.

9. Hydraulic equipment should always be kept clean to prevent various pollutants from entering the oil tank.

10. Before the equipment is operated, the system pressure, noise, and vibration should be fully checked to see if they are stable and within the specified range; whether there is oil leakage in the whole system; whether the voltage is kept within the range of +5% to -15% of the rated voltage.

Technical parameters:

Hydraulic Drive Motor | 18.5KW -4 stage |

Motor Disassembly Torque | 30000N.m |

Total Flow of Hydraulic Motor | 56L/min |

Pumping Station Pressure | 31.5Mpa |

Motor Working Pressure | 25Mpa |

Afterburner Torque | 300000N.m |

Maximum Thrust of The Clamping Cylinder | 265KN |

Maximum Pulling Force | 180KN |

Disassemble The Bore | 50-500 |

Translational Cylinder Stroke | 2100mm |

Secondary Cylinder Clamping | V-shaped tooth plate clamping |

How it Works | Control valve/button electric control/remote control |

Dimensions | 7000×2400×1700mm |

Product configuration:

Name | Model | Quantity |

Motor | 18.5KW | 1 unit |

Hydraulic Motor | HZKY-01-001 | 1 unit |

Oil Pump | HZKY-01-002 | 1 unit |

Control Valves | HZKY-01-003 | 8 groups |

Afterburner Cylinders | HZKY-01-004 | 2 pcs |

Tighten Up Left and Right | HZKY-01-005 | 2 pcs |

Auxiliary Cylinders | HZKY-01-006 | 1 pc |

High-pressure Hose | 34 articles |

Haozhou Mining's hydraulic dismantling machine has become the preferred choice in the field of mining equipment maintenance with its high-torque precision control, high-compatibility design and strict quality control system. Its technology not only solves the long-standing disassembly problems in the industry, but also realizes the competitive advantage of the trinity of "power, intelligence and reliability" through electromechanical and hydraulic collaborative innovation.