Construction Hydraulic Cylinder Maintenance Machine

Multi-model compatibility:

It can be disassembled/assembled with different types of hydraulic support columns, jacks and other large threaded connectors to meet the diverse needs of mines

Precise torque control:

Constant torque tightening technology is used to ensure the firmness of the threaded assembly and avoid equipment failure caused by overtightening or loosening.

Efficient locking mechanism:

Self-positioning locking design: replace the traditional hydraulic clamping, simplify the structure, reduce the failure rate, and operate conveniently and with high reliability.

Safety hydraulics:

The use of mining emulsion as the medium is compatible with the mine's existing pumping station (the pumping station is designed to be separated from the main engine) and reduces maintenance costs.

The hydraulic components are made of common parts for mining, which is easy to replace and repair quickly

Multiple electrical protections:

Integrated overload, short circuit, and loss of voltage protection functions to ensure operation safety and equipment stability

The core structure of the device can be divided into the following functional modules:

Fuselage Frame - as the supporting foundation of the whole machine, to ensure the stability of operation and structural strength.

Clamping and Sliding Mechanism - integrated self-positioning locking function realizes fast clamping and axial displacement adjustment of the workpiece.

Power Transmission Unit - including hydraulic motor, connecting pulley and chuck, forming a torque transmission chain, driving thread disassembly and assembly.

Chuck Assembly - multi-specification adaptation design, directly clamping the column or jack to ensure rotation concentricity.

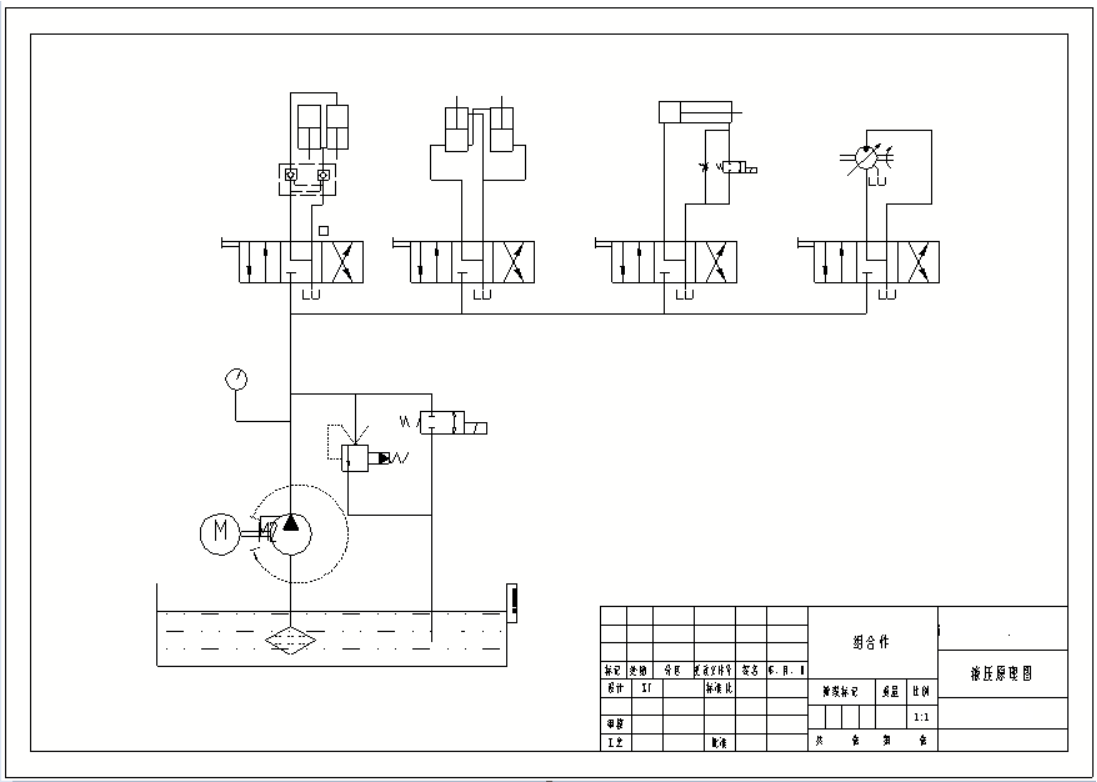

Hydraulic Control Module – the liquid supply (emulsion medium) is supplied through the pumping station, and the motor speed and output torque are adjusted.

Electrical Control Box - integrated protection circuit, management of equipment start-stop, operating parameters and fault diagnosis.

It can disassemble various types of hydraulic support columns and jacks that are firmly assembled with threads.

2. The fixed button torque is tightened and assembled, and various types of hydraulic supports, large columns and jacks are firmly assembled with threads.

3. Disassemble and spin on various large threaded connection components.

4. The self-positioning locking mechanism replaces the original hydraulic clamping mechanism, which has simple structure, convenient operation and reliable operation.

5. The hydraulic medium is mine emulsion, and the pumping station is separated from the main engine.

6. The hydraulic parts are made of general mining parts for maintenance and replacement.

7. The electrical control has the protection of overload, short circuit, loss of voltage, etc. To put it another wayTechnical parameters:

Hydraulic Drive Motor

18.5KW -4 stage

Motor Disassembly Torque

30000N.m

Total Flow of Hydraulic Motor

56L/min

Pumping Station Pressure

31.5Mpa

Motor Working Pressure

25Mpa

Afterburner Torque

300000N.m

Maximum Thrust of The Clamping Cylinder

265KN

Maximum Pulling Force

180KN

Disassemble The Bore

50-500

Translational Cylinder Stroke

2100mm

Secondary Cylinder Clamping

V-shaped tooth plate clamping

How it Works

Control valve/button electric control/remote control

Dimensions

7000×2400×1700mm

Product configuration:

Name

Model

Quantity

Motor

18.5KW

1 unit

Hydraulic Motor

HZKY-01-001

1 unit

Oil Pump

HZKY-01-002

1 unit

Control Valves

HZKY-01-003

8 groups

Afterburner Cylinders

HZKY-01-004

2 pcs

Tighten Up Left and Right

HZKY-01-005

2 pcs

Auxiliary Cylinders

HZKY-01-006

1 pc

High-pressure Hose

34 articles

Precautions for the dismantling process:

In the process of dismantling, the surface of the parts should be well protected from injury, and the parts in contact with the precision workpiece should have leather pads and other protective devices.

When disassembling the guide bushing, the system pressure must be unloaded first, and then the pressure valve must be slowly adjusted to increase the pressure until it can rotate. And do not rotate directly under high pressure to prevent damage to the workpiece and threads.

The hydraulic motor in the system can reach the rated torque at 20Mpa pressure, and the ratchet pendulum can reach 120,000 Nm at 16Mpa pressure. Never use it with overpressure.

Patent Certificate: