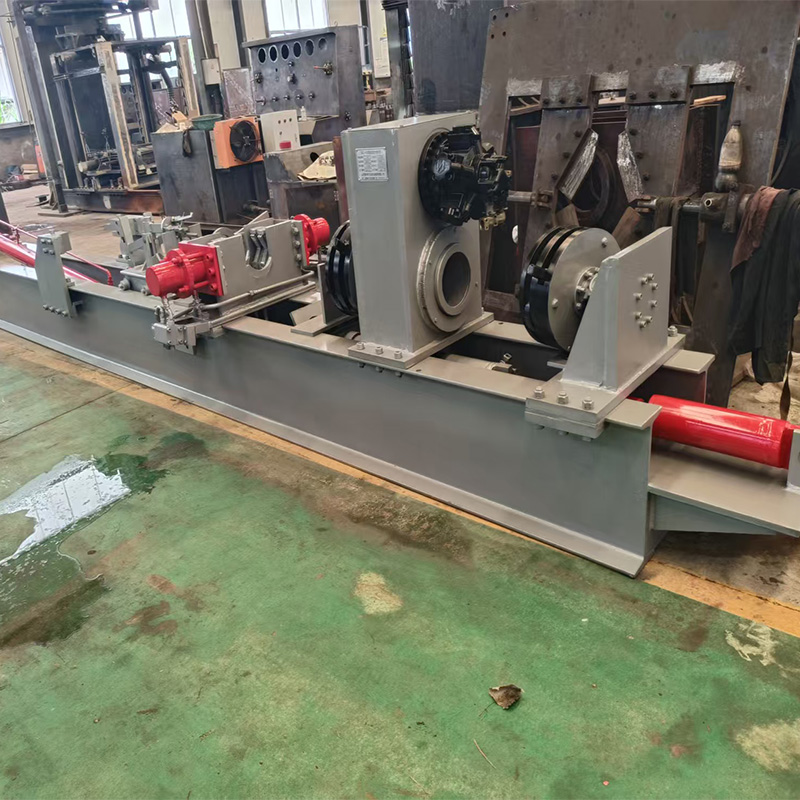

Mobile Hydraulic Prop Extractor For Support Systems

1. Efficient disassembly capability

2. Safety and reliability

3. Safety and reliability

4. Energy conservation and environmental protection

Mobile Hydraulic Prop Extractor For Support Systems:

Mobile Hydraulic Prop Extractor For Support Systems is a specialised disassembly and meeting tools designed for hydraulic help columns, jacks, and different factors in coal mine comprehensive mining. It adopts mechanical, hydraulic, and electrical device linkage manage to reap environment friendly and automatic operations. Its core shape includes:

1. Mobile base: geared up with taking walks wheels or tracks, it can be flexibly moved to the working surface, lowering gear transportation time.

2. Clamping sliding device: Fix the column with a hydraulic chuck or self positioning locking mechanism to adapt to workpieces of unique diameters (such as 200-650mm) and lengths (such as 2200mm).

3. Hydraulic motor transmission: It makes use of a low-speed excessive torque hydraulic motor to pressure rotation, with an preliminary torque of up to 9000N · m, making it effortless to disassemble corroded or threaded components.

4. Long stroke slide table: Equipped with a hydraulic slide desk with a stroke of 1800mm or more, it can entire a couple of methods such as pulling out the energetic column and disassembling the information sleeve in one go.

5. Modular design: integrating practical gadgets such as three-way valve separation and base disassembly, assisting rapid mould substitute to adapt to one-of-a-kind sorts of brackets.

Core blessings and technological innovation:

1. Efficient disassembly capability

Adjustable torque: Real time manage of velocity and torque (range 1000-210000N · m) via hydraulic machine to keep away from harm to tools or workpieces due to overload. For example, the fashions of Warner Electromechanical Equipment Co., Ltd. in Tai'an City can flexibly modify the disassembly pressure to resolve the trouble of thread rust.

Composite action: The hydraulic motor and auxiliary thrust cylinder work together, with a massive preliminary output torque. After the screws are loosened, the hydraulic motor by myself can proceed to disassemble, growing the effectivity of single column disassembly to 15-20 portions per hour (such as CZ-3.5 type).

2. Safety and reliability

Overload protection: The hydraulic machine is geared up with an overflow valve, which mechanically releases strain when the strain exceeds the set price (such as 25MPa) to forestall tools damage.

Self positioning locking: the use of an eccentric bidirectional chuck or adjustable bracket to make certain that the workpiece does now not fall off throughout disassembly and assembly, growing operational security through greater than 50%.

3. Intelligence and usability

Mechatronics hydraulic joint control: Centralized manage via PLC or buttons, assisting features such as ahead and reverse rotation, real-time torque display, etc. Operators can take up their posts after easy training.

Modular mold: By changing the chuck disc cover, it can adapt to one of a kind kinds of giant columns, decreasing gear configuration fees with the aid of 30%.

4. Energy conservation and environmental protection

Emulsion medium: Using a working medium containing 5% emulsion to limit environmental air pollution brought on by way of hydraulic oil leakage.

Low noise design: The belt power shape reduces the running noise to under seventy five decibels, enhancing the working environment.

Application scenarios:

1. Maintenance of coal mine hydraulic supports

Disassembly and meeting of giant columns: Disassemble the information sleeve, movable column, and cylinder physique of single and double telescopic columns, and restore bent or dented oil cylinders. For example, Shandong Haozhou Mining Equipment can dismantle columns with an outer diameter of 200-650mm and a size of 2200mm, assembly the necessities of assisting heights from 3.5m to 8m for completely mechanized mining faces.

Jack maintenance: Horizontal meeting of key or threaded jacks to resolve the hassle of excessive labor depth in guide disassembly.

2. Repair of person hydraulic prop

Rusted pillar treatment: For DZ kind single hydraulic pillars with extreme rusting in mines, environment friendly disassembly is carried out thru bidirectional self tightening chucks (clamping pressure extended via extra than 30%). For example, the CZ-2.5 mannequin can deal with pillars with a peak of 600-4500mm and a cylinder diameter of 100-110mm.

Batch maintenance: integrating features such as three-way valve separation and base disassembly, a single gadget can exchange 3-5 people and expand protection effectivity by means of four times.

3. Other industrial sectors

Building assist equipment: Disassemble hydraulic aid columns all through tunnel excavation to adapt to complicated geological conditions.

Road development machinery: Maintain the column elements of hydraulic pile drivers, telescopic cranes, and different equipment.