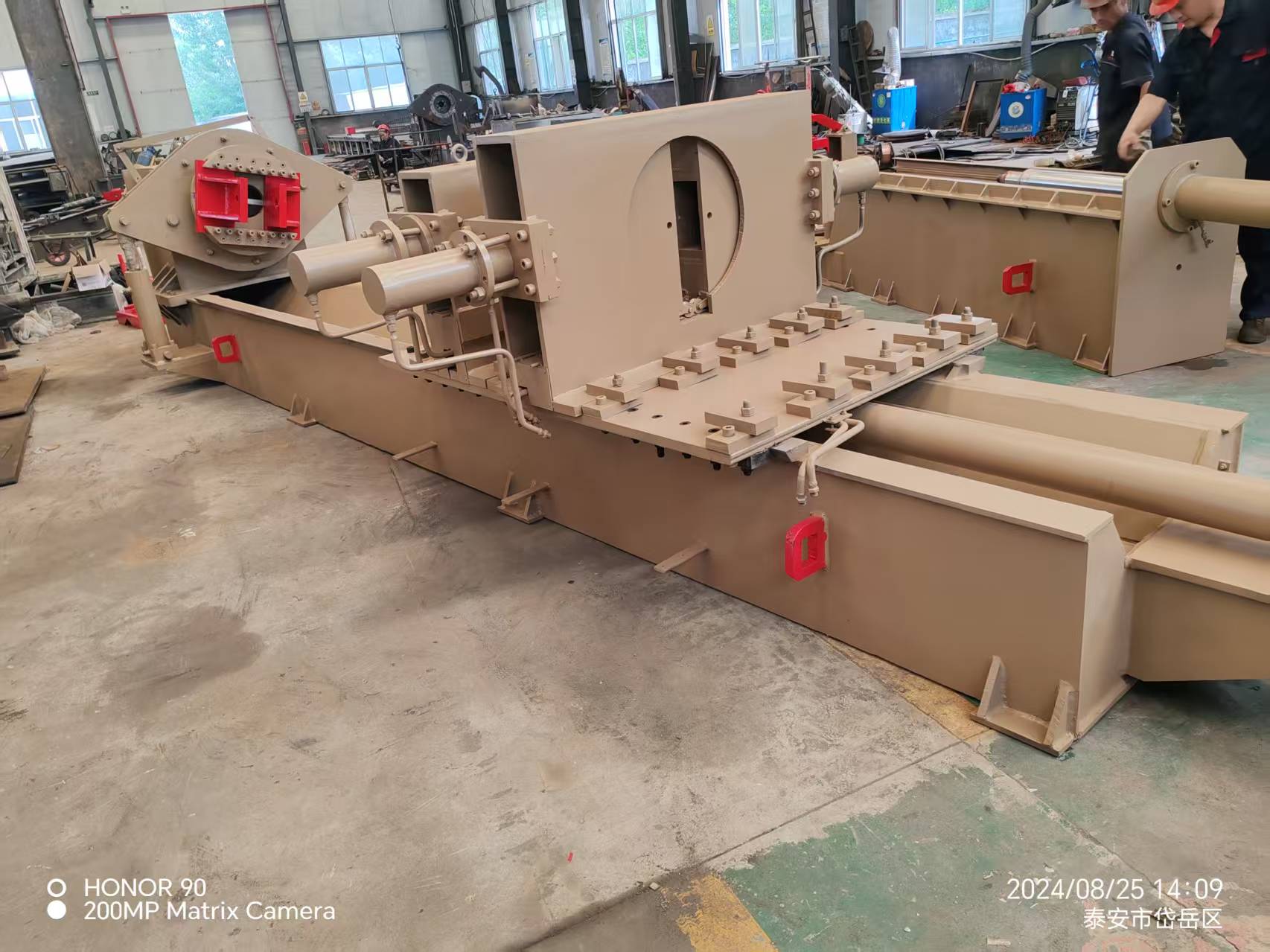

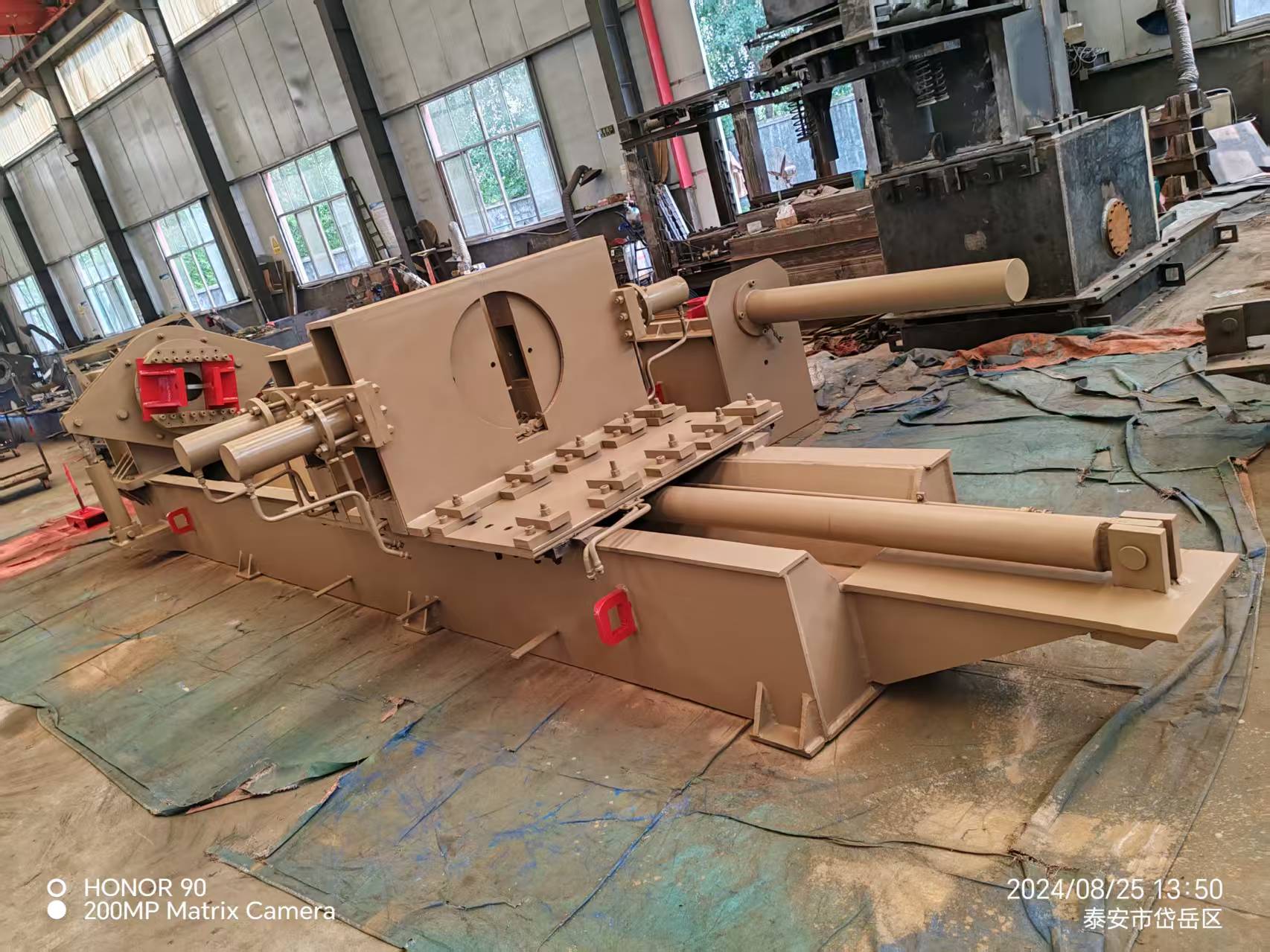

Mini Horizontal Cylinder Servicing Workstation

Basic requirements

1. Personnel qualifications: Operators have to be licensed to work, and they are prohibited from working except expert training.

2. Operation safety: Keep the workshop clean, hold a protected distance at some point of high-pressure testing, and function after stress relief.

3. Inspection and maintenance: Check the pipeline regularly, and deal with abnormalities immediately; disassembled components have to be cleaned and inspected and the substitute listing should be recorded.

4. Sealing requirements: All seals have to be changed all through maintenance.

5. Tool use: Special equipment should be used for disassembly and assembly.

6. Accessory standards: Replacement components need to comply with business enterprise technical requirements and drawing requirements.

7. Test safety: The shielding door need to be closed in the course of strain testing.

Basic operating specifications

1. Operator qualification requirements

All equipment operators and maintenance personnel must pass professional training and obtain corresponding qualification certification. Those who have not passed the assessment are strictly prohibited from working.

2. Working environment safety management

The maintenance workshop must be kept clean and orderly. During the operation, personnel should keep a safe distance from the high-pressure test area. Pipeline disassembly operations must be carried out only after the system is completely depressurized.

3. Equipment inspection and maintenance standards

Periodically carry out pipeline system inspections. If loose connections or worn parts are found, they must be promptly handled and replaced; all disassembled parts must be professionally cleaned and visually inspected, focusing on confirming whether there is deformation, rust or damage, and compiling a detailed spare parts replacement list.

4. Seal replacement regulations

All sealing elements must be replaced during maintenance, and reuse of old seals is prohibited.

5. Special tool use requirements

All disassembly and assembly operations must use certified special tools, and non-standard or homemade tools are strictly prohibited.

6. Parts replacement standards

Maintenance parts must strictly comply with enterprise technical standards and product drawing requirements. Any parts that do not meet technical specifications are prohibited from use.

7. Safety test procedures

When conducting pressure tests, the protective cabinet door must be closed to prevent personal injury from workpiece or liquid splashing during the test.

Technical parameters:

Hydraulic Drive Motor | 18.5KW -4 stage |

Motor Disassembly Torque | 30000N.m |

Total Flow of Hydraulic Motor | 56L/min |

Pumping Station Pressure | 31.5Mpa |

Motor Working Pressure | 25Mpa |

Afterburner Torque | 300000N.m |

Maximum Thrust of The Clamping Cylinder | 265KN |

Maximum Pulling Force | 180KN |

Disassemble The Bore | 50-500 |

Translational Cylinder Stroke | 2100mm |

Secondary Cylinder Clamping | V-shaped tooth plate clamping |

How it Works | Control valve/button electric control/remote control |

Dimensions | 7000×2400×1700mm |

Product configuration:

Name | Model | Quantity |

Motor | 18.5KW | 1 unit |

Hydraulic Motor | HZKY-01-001 | 1 unit |

Oil Pump | HZKY-01-002 | 1 unit |

Control Valves | HZKY-01-003 | 8 groups |

Afterburner Cylinders | HZKY-01-004 | 2 pcs |

Tighten Up Left and Right | HZKY-01-005 | 2 pcs |

Auxiliary Cylinders | HZKY-01-006 | 1 pc |

High-pressure Hose | 34 articles |