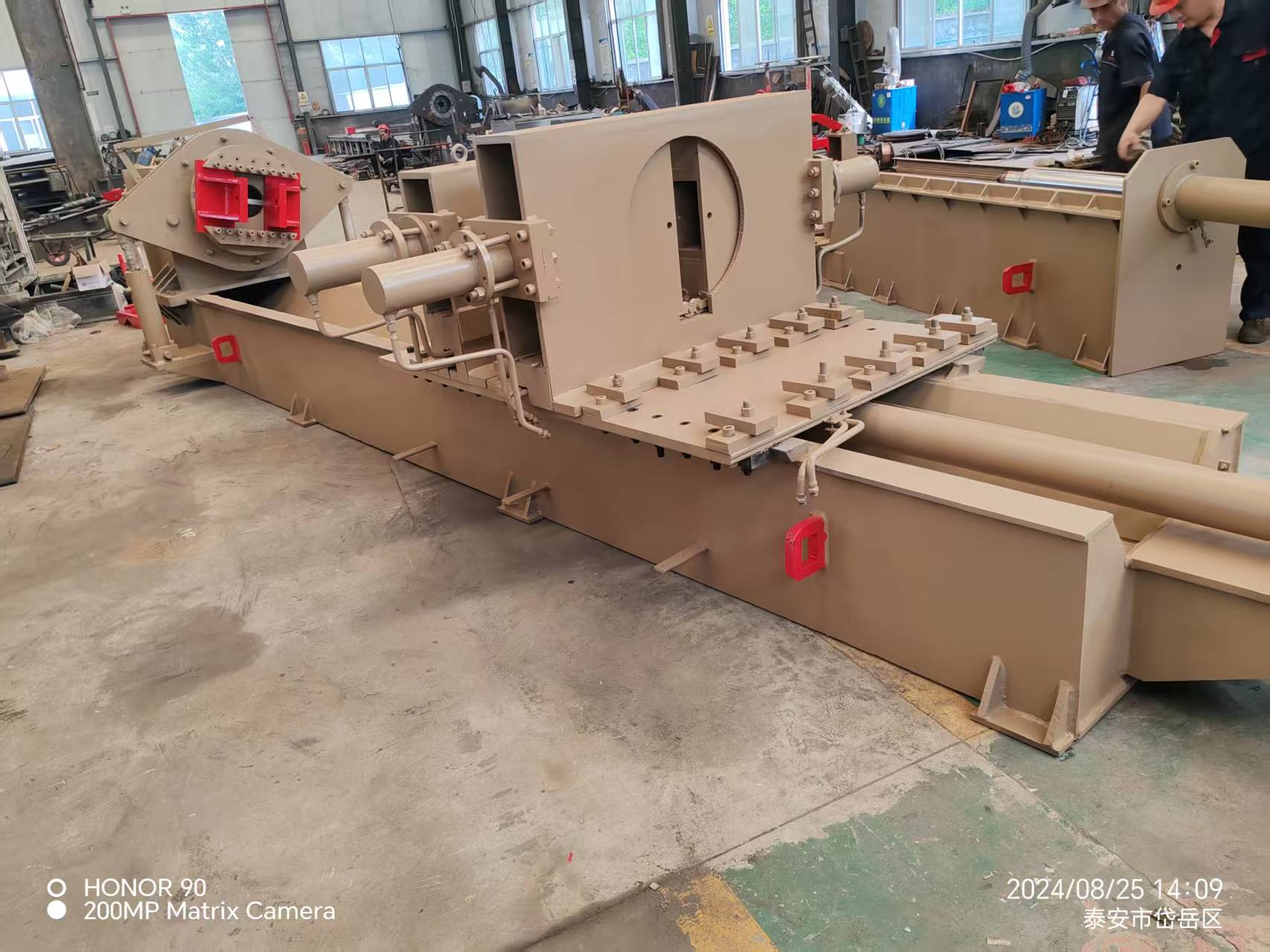

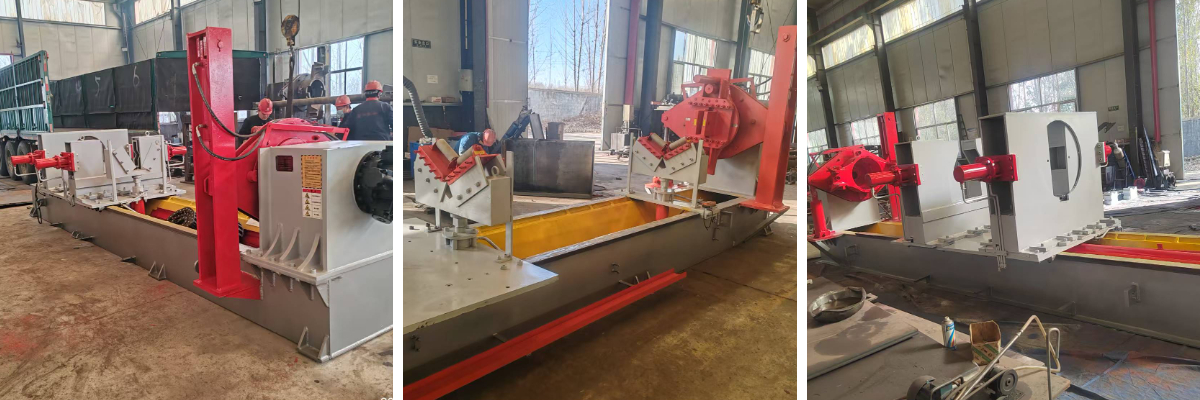

Portable Horizontal Cylinder Teardown System

1. Before disassembly, the cylinder physique desires to be cleaned with excessive strain and a ±0.2mm tolerance die sleeve need to be prepared.

2. When hoisting, manage the inclination attitude of 3°, modify the axial ≤0.5mm/radial ≤φ0.1mm centering, and make certain that the die meshing clearance is ≤0.3mm.

3. A 16MPa hydraulic motor is used for popular disassembly. When rusted, a 20MPa ratchet mechanism is enabled, and a 25MPa difficult restriction is set to stop overpressure.

1. Before disassembly and assembly, high-pressure cleaning equipment (≥10MPa) must be used to thoroughly remove coal ash, oil and other pollutants on the surface of the cylinder body, and a special clamping sleeve with a corresponding accuracy tolerance of ±0.2mm should be prepared according to the specifications of the cylinder guide sleeve to be disassembled (such as 400mm double-extended columns) to ensure the matching of the tooling.

2. During hoisting, use anti-slip slings to stably hoist the cylinder body to the cylinder disassembly machine at an inclination angle of ≤3°, adjust the axial center by clamping the rear screw of the cylinder (deviation ≤0.5mm) and use the centering mechanism to adjust the radial concentricity (≤φ0.1mm), and finally move the workbench to keep the clamping sleeve and the chuck support mouth with a gap of ≤0.3mm and accurately mesh.

3. The standard disassembly process gives priority to using a 16MPa hydraulic motor to directly loosen the guide sleeve. In case of rust, the ratchet auxiliary mechanism with a maximum pressure of 20MPa can be started. In case of severe biting, a thermal disassembly process of ≤150℃ is used, and a 25MPa system hard limit is set to prevent overpressure operation.

4. Two process paths are provided for disassembly:

Mode A (preferred): middle cylinder guide sleeve → outer cylinder guide sleeve → outer cylinder separation → bottom valve operation → live column ejection

Mode B (alternative): outer cylinder guide sleeve → middle cylinder separation → middle cylinder reinstallation → clamp plate fixation → live column ejection Mode A disassembles the middle cylinder guide sleeve and outer cylinder guide sleeve in sequence and then ejects the live column; Mode B first disassembles the outer cylinder guide sleeve and then processes the middle cylinder assembly. In actual operation, the selection should be based on the working conditions and the specific parameters can be optimized and adjusted under the guidance of the supervision engineer.

5. Rubber pads with a Shore hardness of 60±5 must be used throughout the operation to protect the precision contact surface. The pressure adjustment must be reset to zero and then gradually increased at a rate of ≤2MPa/s. The pressure sensor must be calibrated monthly according to the MT/T 98-2016 standard. If the card die sleeve is worn >0.5mm, it must be scrapped and replaced immediately.