Hydraulic Cylinder Horizontal Dismantling Machine

1. It can disassemble various types of hydraulic support columns and jacks that are firmly assembled with threads.

2. The fixed button torque is tightened and assembled, and various types of hydraulic supports, large columns and jacks are firmly assembled with threads.

3. Disassemble and spin all kinds of large threaded connection components.

4. The self-positioning locking mechanism replaces the original hydraulic clamping mechanism, which has simple structure, convenient operation and reliable operation.

5. The hydraulic medium is made of mining emulsion, and the pumping station is separated from the main engine.

6. The hydraulic parts are made of general mining parts for maintenance and replacement.

7. The electrical control has the protection of overload, short circuit, loss of voltage, etc.

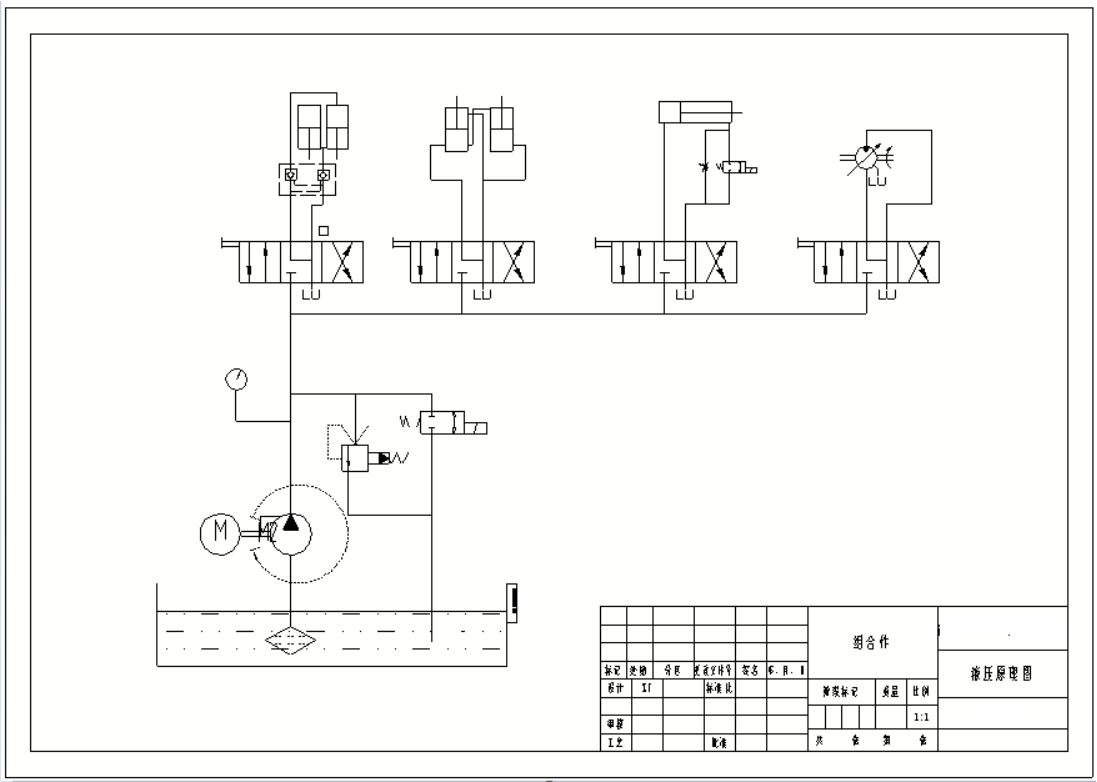

Hydraulic cylinder horizontal dismantling machine is mainly composed of a fuselage, a clamping and sliding device, a connecting roller, a chuck, a hydraulic motor transmission device, a hydraulic operating system, an electrical control system, etc.

Operation qualification requirements :

operators need to fully grasp the working principle of the hydraulic system and the function of each component

must be familiar with the equipment action process and operating procedures

operation monitoring requirements :

real-time monitoring of the system pressure and actuator speed

to ensure stable and reliable operation of the hydraulic system

check before starting :

to confirm that the multi-way reversing valves and moving institutions in the initial state

check the oil level of the oil tank, abnormalities prohibit the start-up and report for repairs

Temperature control standards :

oil temperature <15 ℃ prohibit operation, need to preheat the cooling system and cool down the normal temperature range of 15 ℃ long term shutdown operation Prohibit operation when the oil temperature is less than 15℃, need to warm up to the working temperature

Check the cooling system and cool down when the oil temperature is more than 50℃

Normal working temperature range: 15-50℃

Long-term shutdown operation :

After stopping for more than 4 hours, need to run the hydraulic pump for 3-5 minutes with no load

Confirm that the system is normal before loading the work

Safe Operation Prohibition :

Unauthorized change of the electrical interlocking device is prohibited

Prohibition of adjusting the operating block position

Unauthorized adjustment or replacement of hydraulic components Troubleshooting Procedures Replacement of hydraulic components

Troubleshooting Procedure :

Stop immediately when abnormalities are detected and report to the maintenance department

Private disassembly for maintenance is prohibited

Daily maintenance requirements :

Keep the equipment clean and prevent contaminants from entering the system

Pre-operation inspection:

System pressure, noise, vibration status

Sealability of the pipeline (no leakage)

Voltage fluctuation range (±5%~-15%)

Periodic Maintenance System

Establish a cyclical inspection plan

Key inspection items:

Hydraulic components Working condition

Electrical system reliability

Mechanical structure integrity

Maintenance records must be completely archived

Technical parameters:

Hydraulic Drive Motor | 18.5KW -4 stage |

Motor Disassembly Torque | 30000N.m |

Total Flow of Hydraulic Motor | 56L/min |

Pumping Station Pressure | 31.5Mpa |

Motor Working Pressure | 25Mpa |

Afterburner Torque | 300000N.m |

Maximum Thrust of The Clamping Cylinder | 265KN |

Maximum Pulling Force | 180KN |

Disassemble The Bore | 50-500 |

Translational Cylinder Stroke | 2100mm |

Secondary Cylinder Clamping | V-shaped tooth plate clamping |

How it Works | Control valve/button electric control/remote control |

Dimensions | 7000×2400×1700mm |

Product configuration:

Name | Model | Quantity |

Motor | 18.5KW | 1 unit |

Hydraulic Motor | HZKY-01-001 | 1 unit |

Oil Pump | HZKY-01-002 | 1 unit |

Control Valves | HZKY-01-003 | 8 groups |

Afterburner Cylinders | HZKY-01-004 | 2 pcs |

Tighten Up Left and Right | HZKY-01-005 | 2 pcs |

Auxiliary Cylinders | HZKY-01-006 | 1 pc |

High-pressure Hose | 34 articles |

Vertical cylinder disassembly and assembly machine shipyard installation and commissioning site