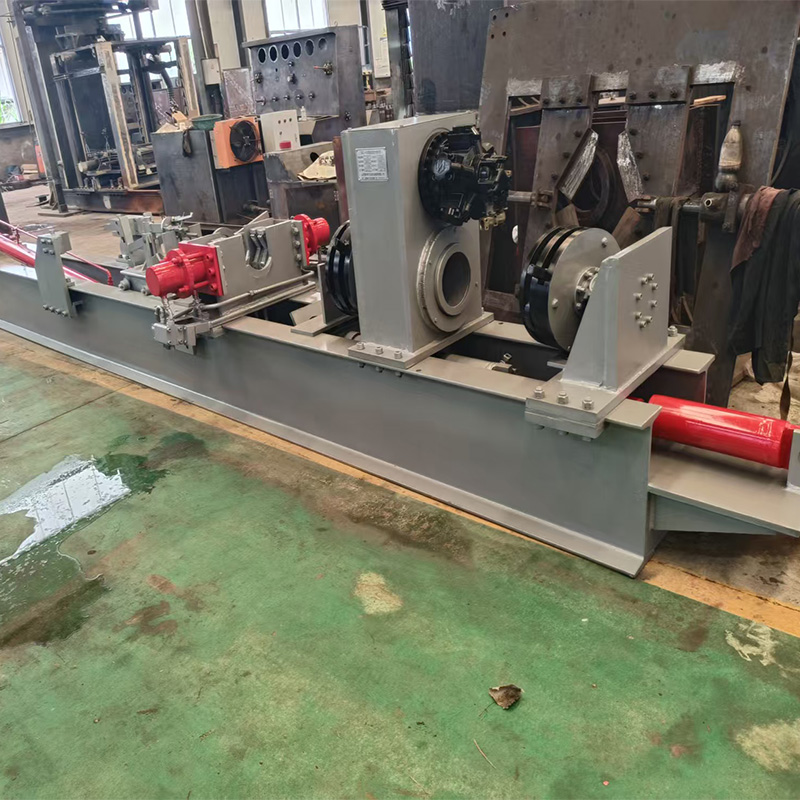

Walking Hydraulic Support Prop Disassembler

1. Efficient disassembly capability

2. Safety and reliability

3. Safety and reliability

4. Energy conservation and environmental protection

Walking Hydraulic Support Prop Disassembler:

Walking Hydraulic Support Prop Disassembler is a specialized disassembly and assembly equipment designed for hydraulic support columns, jacks, and other components in coal mine comprehensive mining. It adopts mechanical, hydraulic, and electrical system linkage control to achieve efficient and automated operations. Its core structure includes:

1. Mobile base: equipped with walking wheels or tracks, it can be flexibly moved to the working surface, reducing equipment transportation time.

2. Clamping sliding device: Fix the column with a hydraulic chuck or self positioning locking mechanism to adapt to workpieces of different diameters (such as 200-650mm) and lengths (such as 2200mm).

3. Hydraulic motor transmission: It uses a low-speed high torque hydraulic motor to drive rotation, with an initial torque of up to 9000N · m, making it easy to disassemble corroded or threaded components.

4. Long stroke slide table: Equipped with a hydraulic slide table with a stroke of 1800mm or more, it can complete multiple processes such as pulling out the active column and disassembling the guide sleeve in one go.

5. Modular design: integrating functional units such as three-way valve separation and base disassembly, supporting quick mold replacement to adapt to different types of brackets.

Core advantages and technological innovation:

1. Efficient disassembly capability

Adjustable torque: Real time control of speed and torque (range 1000-210000N · m) through hydraulic system to avoid damage to equipment or workpieces due to overload. For example, the models of Warner Electromechanical Equipment Co., Ltd. in Tai'an City can flexibly adjust the disassembly force to solve the problem of thread rust.

Composite action: The hydraulic motor and auxiliary thrust cylinder work together, with a large initial output torque. After the screws are loosened, the hydraulic motor alone can continue to disassemble, increasing the efficiency of single column disassembly to 15-20 pieces per hour (such as CZ-3.5 type).

2. Safety and reliability

Overload protection: The hydraulic system is equipped with an overflow valve, which automatically releases pressure when the pressure exceeds the set value (such as 25MPa) to prevent equipment damage.

Self positioning locking: using an eccentric bidirectional chuck or adjustable bracket to ensure that the workpiece does not fall off during disassembly and assembly, increasing operational safety by more than 50%.

3. Intelligence and usability

Mechatronics hydraulic joint control: Centralized control through PLC or buttons, supporting functions such as forward and reverse rotation, real-time torque display, etc. Operators can take up their posts after simple training.

Modular mold: By replacing the chuck disc cover, it can adapt to different types of large columns, reducing equipment configuration costs by 30%.

4. Energy conservation and environmental protection

Emulsion medium: Using a working medium containing 5% emulsion to reduce environmental pollution caused by hydraulic oil leakage.

Low noise design: The belt drive structure reduces the operating noise to below 75 decibels, improving the working environment.

Application scenarios:

1. Maintenance of coal mine hydraulic supports

Disassembly and assembly of large columns: Disassemble the guide sleeve, movable column, and cylinder body of single and double telescopic columns, and repair bent or dented oil cylinders. For example, Shandong Haozhou Mining Equipment can dismantle columns with an outer diameter of 200-650mm and a length of 2200mm, meeting the requirements of supporting heights from 3.5m to 8m for fully mechanized mining faces.

Jack maintenance: Horizontal assembly of key or threaded jacks to solve the problem of high labor intensity in manual disassembly.

2. Repair of individual hydraulic prop

Rusted pillar treatment: For DZ type single hydraulic pillars with severe rusting in mines, efficient disassembly is achieved through bidirectional self tightening chucks (clamping force increased by more than 30%). For example, the CZ-2.5 model can handle pillars with a height of 600-4500mm and a cylinder diameter of 100-110mm.

Batch maintenance: integrating functions such as three-way valve separation and base disassembly, a single device can replace 3-5 workers and increase maintenance efficiency by 4 times.

3. Other industrial sectors

Building support equipment: Disassemble hydraulic support columns during tunnel excavation to adapt to complex geological conditions.

Road construction machinery: Maintain the column components of hydraulic pile drivers, telescopic cranes, and other equipment.