Horizontal Hydraulic Cylinder Disassembly and Assembly Equipment

1. It can disassemble various types of hydraulic support columns and jacks that are firmly assembled with threads.

2. The fixed button torque is tightened and assembled, and various types of hydraulic supports, large columns and jacks are firmly assembled with threads.

3. Disassemble and spin all kinds of large threaded connection components.

4. The self-positioning locking mechanism replaces the original hydraulic clamping mechanism, which has simple structure, convenient operation and reliable operation.

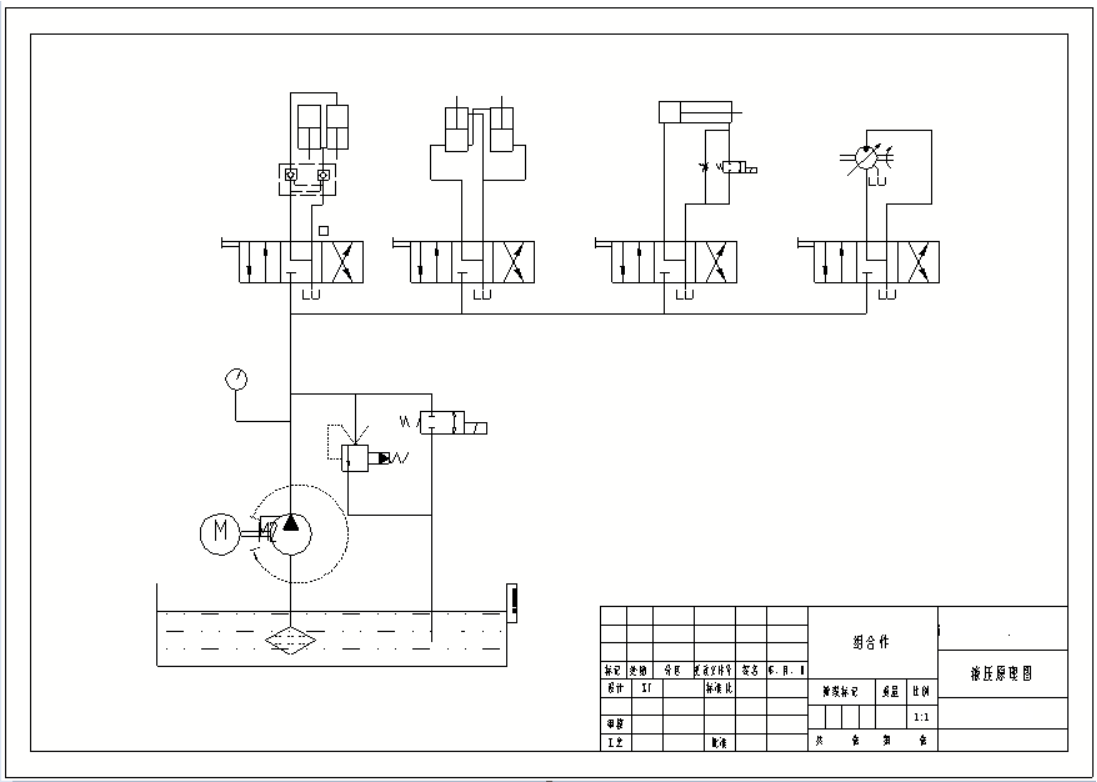

5. The hydraulic medium is made of mining emulsion, and the pumping station is separated from the main engine.

6. The hydraulic parts are made of general mining parts for maintenance and replacement.

7. The electrical control has the protection of overload, short circuit, loss of voltage, etc.

The machine is mainly composed of a fuselage, a clamping and sliding device, a connecting roller, a chuck, a hydraulic motor transmission device, a hydraulic operating system, an electrical control system, etc.

Product Introduction:

Horizontal hydraulic cylinder disassembly and assembly equipment is a high-efficiency tool specially developed for the dismantling and assembly of hydraulic cylinders for fully mechanized mining supports in coal mines, and its performance has been significantly improved after in-depth optimization and technological innovation on the basis of traditional models. It is designed to be suitable for all kinds of fully mechanized mining support hydraulic cylinders with threaded connection end covers, which can meet the maintenance and assembly needs of different models, and is a reliable solution for the maintenance of hydraulic supports in coal mines.

The Use and Procedures of Disassembly and Assembly:

The large column cylinder must be thoroughly cleaned externally before disassembly and assembly to remove coal ash, grease and other stolen goods on its surface. Before hoisting, it is necessary to find out the specifications and models of the cylinder guide sleeve, and use the corresponding guide sleeve clamping mold to be prepared.

Now according to the 400mm bore double-extension column as an example, a brief introduction to the process of disassembly and assembly. In practice, there may be better operation methods, and they can be continuously improved to achieve the purpose of multiple good savings.

Lift the cleaned column onto the cylinder dismantling machine with a sling, and start the clamping cylinder in the centering position. The center point of the column is adjusted by adjusting the screw behind the clamping cylinder. When the column is clamped, the center point of the column and the chuck is adjusted by adjusting the centering mechanism in front.

After the center is aligned, put on the corresponding card mold sleeve, and move the workbench forward, so that the card mold sleeve and the chuck branch on the disassembly machine are staggered. Then turn on the motor to rotate, and under normal circumstances, the guide sleeve can be removed directly under the pressure of 16Mpa. If there is rust and biting, you need to start the ratchet mechanism to increase the disassembly force to remove the guide sleeve thread.

Technical parameters:

Hydraulic Drive Motor | 18.5KW -4 stage |

Motor Disassembly Torque | 30000N.m |

Total Flow of Hydraulic Motor | 56L/min |

Pumping Station Pressure | 31.5Mpa |

Motor Working Pressure | 25Mpa |

Afterburner Torque | 300000N.m |

Maximum Thrust of The Clamping Cylinder | 265KN |

Maximum Pulling Force | 180KN |

Disassemble The Bore | 50-500 |

Translational Cylinder Stroke | 2100mm |

Secondary Cylinder Clamping | V-shaped tooth plate clamping |

How it Works | Control valve/button electric control/remote control |

Dimensions | 7000×2400×1700mm |

Product configuration:

| Name | Model | Quantity |

| Motor | 18.5KW | 1 unit |

| Hydraulic Motor | HZKY-01-001 | 1 unit |

| Oil Pump | HZKY-01-002 | 1 unit |

| Control Valves | HZKY-01-003 | 8 groups |

| Afterburner Cylinders | HZKY-01-004 | 2 pcs |

| Tighten Up Left and Right | HZKY-01-005 | 2 pcs |

| Auxiliary Cylinders | HZKY-01-006 | 1 pc |

| High-pressure Hose | 34 articles |

Company Introduction:

Shandong Haozhou Mining Safety Equipment Co., Ltd. is located at the foot of the well-known Mount Tai - Daolang Town, Daiyue District, Tai'an City, with a superior geographical location, only 15 kilometers away from the city. The company has a total investment of 60 million yuan, covers an area of 23 acres, and has built a modern standard factory building of 8,000 square meters, which has been fully put into production and operation.

As a high-tech enterprise focusing on mining safety equipment, Haozhou Mining is mainly committed to the R&D and manufacturing of column disassembly equipment, hydraulic pillar maintenance equipment, coal mine roof dynamic monitoring system and various mine pressure observation instruments. The company integrates product design, technology development, manufacturing, equipment installation and after-sales service, providing customers with a full range of mining safety solutions to help coal mines operate efficiently and safely.

Patent Certificate: